AERATION & BLOWERS RESOURCES

-

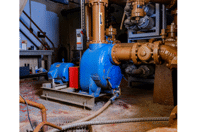

The overall wastewater treatment process is complex, and each step is integral to ensuring water is properly purified. Effluent ends up in the plants, containing substances that must be removed before the water can be properly cleaned and returned for use. The range of potential contaminants is almost endless, and can include food, pulp, waste, or other substances. Afterwards, the water requires further scrubbing, with the aid of bacteria. It is in this part of the process that compressed air (ideally provided by energy-efficient rotary lobe blowers) plays a vital role.

-

Learn how a wastewater treatment plant replaced their existing aeration system, realizing better treatment and 50% savings in operating costs.

-

Explore how a wastewater treatment plant realized significant energy savings and increased performance with adaptive mixer technology.

-

The City of Shelby, Ohio recently upgraded its activated-sludge wastewater treatment plant to double its capacity to 5 MGD, while expanding its capability to treat and disinfect combined high-volume stormwater and wastewater flows generated by wet-weather conditions.

-

In this case study, discover how a WWTP used a Mazzei aeration system to continue meeting its permit requirements without adding to the daily responsibilities of plant personnel.

-

Read how Mazzei provided aeration equipment to a water purification facility in Yankton, South Dakota, that was conveniently installed out of sight in the building's basement.

-

In the daily rush to ensure that all the mechanical, electrical, and operational procedures are followed — monitoring inflow volumes and organic/nutrient loads; servicing and maintaining motors, pumps, and other electrical and mechanical equipment; maintaining chemical treatments to ensure effluent compliance — it is too easily forgotten that wastewater treatment is primarily a biological process.

-

Aire-02 was approached by a large sugar beet processing facility that was in desperate need of a rapid and effective solution for their deteriorating wastewater treatment system.

-

Process control is key to maximizing wastewater treatment efficiency while minimizing operating costs. Implementing the right process control system in conjunction with the right equipment can save money on electrical costs and equipment maintenance.

-

Bose Cascade’s Ft. Frances, Ontario kraft mill operation faced a wastewater treatment problem due to dead spots in nearly half of its aerated stabilization basin. Newterra's Aire-O2 came to the rescue.