FLUSHABLES RESOURCES

-

When the Kearney, MO wastewater treatment plant began plans to upgrade its headworks they choose JWC Environmental’s Brushless Finescreen Monster to replace its old coarse screen.

-

With Xylem's Flygt Concertor solution, Rice University now avoids clogs and callouts caused by grease and debris, as well as costly recurring equipment replacement.

-

Learn about the innovative pumping technology that eliminates clogging, saving time and money for an Oregon utility.

-

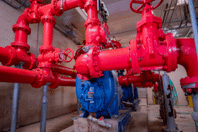

The rise in the use of disposable wipes and other non-dispersible debris is driving the need for more efficient handling of solids in pumps at municipal lift stations and wastewater treatment plant headworks.

-

Explore how a wastewater treatment plant in Pottsville, Pennsylvania, addressed clogging and maintenance issues with the Duperon Dual Auger System.

-

The Drake Pump Station, located in Saginaw, Michigan experienced chronic pump maintenance due to flushable wipes. Although the dry pit pump station represented only 0.1 million gallons per day (mgd) of flow in the city’s collection network, it required a substantial amount of servicing – up to three times a week. This consisted of two operators spending four hours manually removing rags in a confined space entry to clean out the clogged pump. It was a dirty, unplanned, and time-consuming task.

-

Wastewater treatment plant operators have dealt with clogging problems at their plants and pump stations for decades, but the meteoric rise in the use of disposable wipes and other non-dispersible products has accelerated the problem to epidemic proportions.

-

Sulzer-led award-winning project improves performance and control of sewage pumping stations.

-

Toilet paper. The most essential product necessary to life besides food and water. Also cited as the first item to run out at supermarkets during an emergency. For those who live in disaster-prone areas, keeping a stockpile is normal. But for everyone else, a few extra rolls of toilet paper is just a routine part of a grocery trip. So what happened when families everywhere panic bought toilet paper to get through an extended lockdown?

-

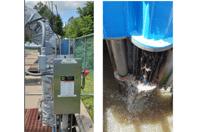

The water treatment needs of both Ukiah Valley and Lake County are served by the Ukiah Wastewater Treatment Plant. Nestled between Highway 101 on the west and the Russian River to the east, the facility features a scenic view of surrounding valleys of vineyards seemingly out of a Steinbeck novel. Construction of the facility was completed in 1958 back when the city had a population of around 9,000. Since then, the population has grown by about 78% to a total of 16,000 residents. The plant’s five pumps are equipped to handle 2.8 MGD (million gallons per day) of dry weather flow, and 20 MGD of wet weather flow. Even though the plant is equipped to remove some floating material, they were having issues with an overflow of unwanted debris.